Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Current Region:

Global (EN)

Global (EN)

The multiple uses of water make it an important resource for human activities.

First, water is necessary for the human organism.

Also, its quality can lead to dramatic consequences if it is the vector of pathogenic micro-organisms or pollution.

Even with good quality water, treatment must be considered to ensure correct quality. In most cases, the production of drinking water requires the use of chemical or other additives, liquid or soluble, to achieve the objectives set by local governments (organoleptic, physico-chemical and microbiological parameters). As the devices used in the water treatment process are in contact with water, some legislation also sets objectives for its contamination through the migration of particles from the equipment to the water.

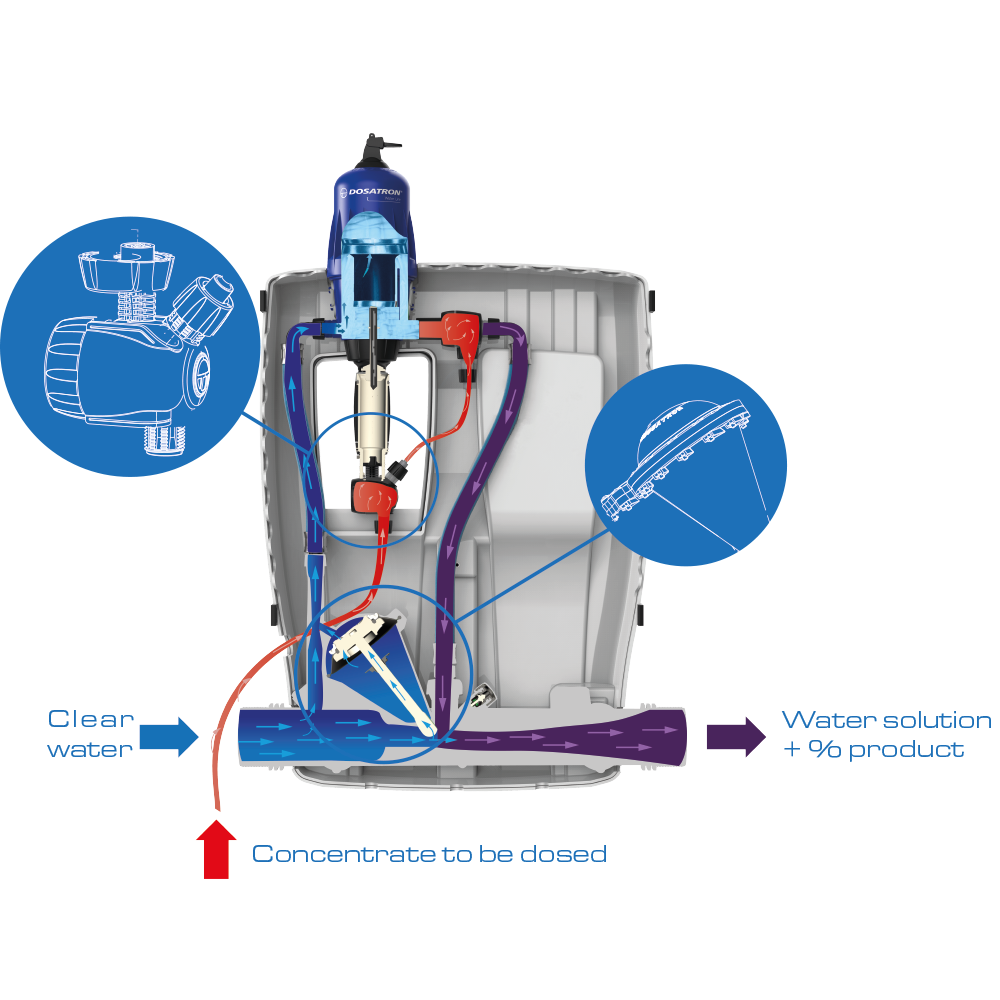

Installed directly on the water supply line, the certified chlorine dosing pump works with the water in your network as the only source of energy.

The pressure and flow of water drives the engine piston, which is itself connected to a metering piston. Chlorine or other disinfection chemicals are proportionally dosed and continuously injected with water at the chosen dosage. The dose of concentrated product is directly proportional to the volume of water flowing through the dosing pump, regardless of variations in the flow rate and pressure of the water supply to the network.

Self-priming up to 4 meters, our dosing pumps are suitable for degassing products, they guarantee the homogeneity of the dilution. They allow direct reading and easy adjustment of the dosage value.

The NSF/ANSI 61 & 372 standard was developed to establish requirements for potential adverse effects on public health of equipment in contact with drinking water (production, transport).

The NSF/ANSI 61 & 372 certified chlorine dosing pumps were subjected to a detailed toxicological analysis. The composition of each device (sub-assemblies, materials, suppliers) was analyzed and referenced by NSF International. Each device has undergone release tests to confirm that harmful particles do not migrate into the water.

The integration of NSF/ANSI 61 & 372 certified chlorine dosing pumps in water treatment applications offers a real alternative to standard dosing technologies, providing precision, robustness and ease of maintenance while protecting the health of users.

Dosatron chlorine dosing pumps certified by the ACS comply with the quality requirements set out in the French Public Health Code (CSP) transposing Directive 98/83/EC of 3 November 1998 on the quality of water intended for human consumption.

The validity of a certificate can be verified by contacting the issuing laboratory, or by consulting the list of valid health certificates of conformity published by the Carso Group laboratories.

The pump technology :

A flow divider in the lower part (patented technology) which ensures a continuous flow division with a constant ratio of the input flow.

A certified chlorine dosing pump in the upper part ensuring the dosing of the desired additive, in proportion to the flow rate supplied by the flow divider.

As all Dosatron dosing pumps, the dosing of the additive by the system as a whole is proportional to the volume of water, regardless of the variations in pressure and flow rate that may occur.

About DOSATRON

Water-powered proportional dosing pumps manufacturer since 1974. DOSATRON provides you with quality fluid handling equipment, service excellence, a high level of expertise, and customer proximity all over the world.